What is Perfect Binding?

In this article we will discuss:

What is Perfect Binding?

How Does Perfect Binding Work?

Alternative Names for Perfect Binding

Advantages of Perfect Binding

Disadvantages of Perfect Binding

Who Uses Perfect Binding?

Leading Perfect Binding Brands

Perfect Binding Machine Comparison

Perfect Binding Video Resources

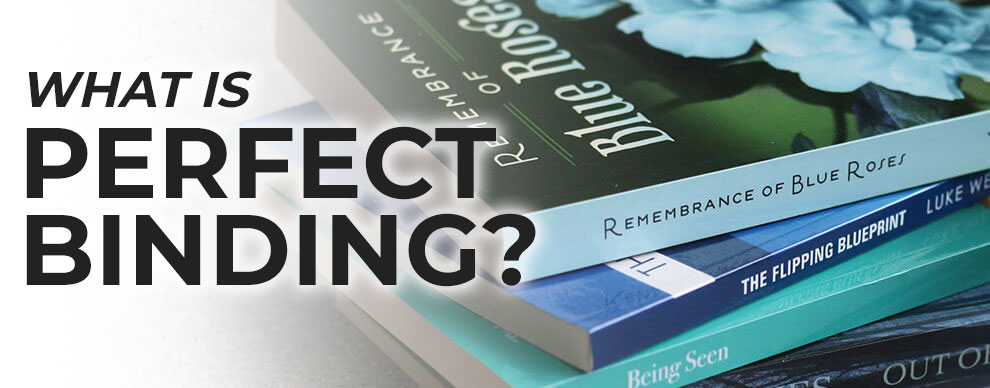

What Is Perfect Binding?

If you’ve ever held a commercial paperback book, you’ve experienced perfect binding. Interestingly, the term "perfect" doesn’t actually refer to the quality of the binding itself. Instead, it describes the flat, even binding created by using strong, flexible thermal glue to attach multiple folded pages. After gluing, the pages are uniformly trimmed on three sides, resulting in an organized and “perfect” set of edges, which you typically don’t see in hardcover books. Perfect-bound books have a professional look, stack neatly, and present well on shelves or displays.

Because of its polished look and cost-effectiveness, perfect binding is popular among businesses, organizations, writers, and publishing companies for a variety of print projects.

How Does Perfect Binding Work?

Perfect binding, also known as softcover binding, is a method where the interior pages are clamped and glued at the spine before being wrapped in a soft cover. The cover and pages are then trimmed on the edges opposite the spine to create a clean, “perfect” edge.

Although the design of a perfect-bound book can vary depending on the machinery, the core steps in the perfect binding process are generally the same. Here’s a detailed look at the process:

The process begins by arranging the printed and folded pages into a book block. The book block is then carried spine-side down through the binder. A clamp moves the book block across a knife that grinds the spine and removes the folds. The spine is further roughened using brushes or sandpaper to expose the paper fibers, which helps the adhesive stick better.

Next, the book block passes through a glue station, where a hot-melt adhesive, typically Polyurethane Reactive (PUR) glue, is applied to the spine. After applying the spine glue, a different hot-melt adhesive is applied to the sides of the spine that will attach to the cover. A metering roller removes excess glue, ensuring the adhesive evenly covers the spine.

Once the glue is applied, the book block is scored along the spine, allowing the cover to fold neatly around it. The cover is then pressed into place, and the book is sent to a trimmer where three large blades trim the edges for a clean finish. The glue typically takes about 45 seconds to set for trimming, but it fully dries in around eight hours.

Some perfect binding machines can bind up to 360 books per hour!

Alternative Names for Perfect Binding

Perfect binding is also known as softcover binding or adhesive binding.

Advantages of Perfect Binding

Perfect binding offers several benefits:

Cost-Effective: Perfect binding is more affordable than hardcover binding techniques and can be used for smaller print runs, making it a budget-friendly option.

Speed: This method is faster than traditional sewing techniques, speeding up the bookbinding process. Even manual systems can bind a book in as little as 20 seconds.

Clean and Professional Appearance: Perfect-bound books stack neatly and have a professional look, making them visually appealing on shelves and displays.

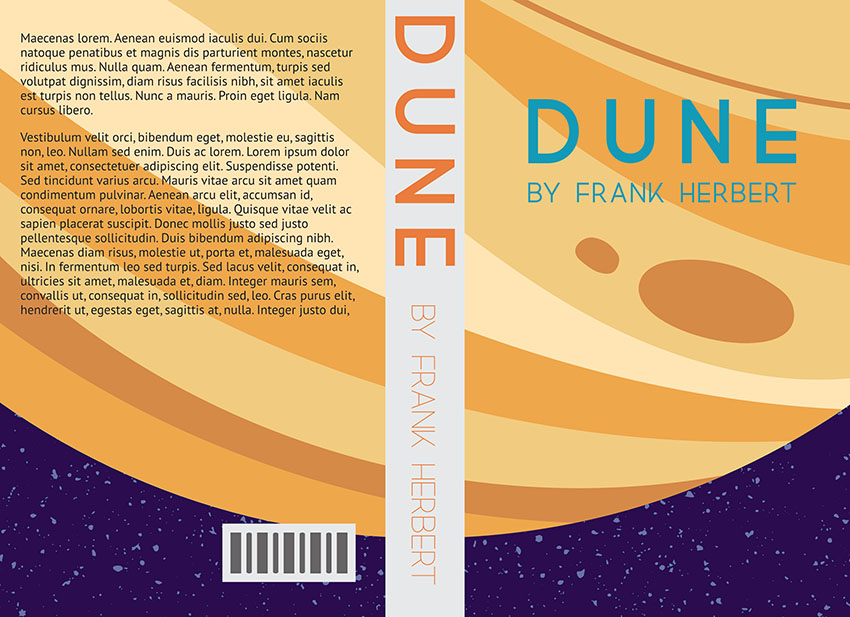

Customization: The square spine allows for printing the book's title or other information, enabling easy customization without additional equipment.

Disadvantages of Perfect Binding

Despite its advantages, perfect binding has some drawbacks:

Thinner Covers: The covers of perfect-bound books are more flexible and thinner than hardcover options, which may cause them to lose shape over time.

Won’t Lay Flat: Perfect-bound books don’t lay flat, making hands-free reading difficult. The adhesive on the spine may also weaken with repeated use.

Gutter Space: The inner margins, known as “gutter” space, can cause some design elements to be lost. This makes perfect binding less suitable for products like recipe books, instruction manuals, or calendars.

Who Uses Perfect Binding?

Perfect binding is widely used by print and finishing shops of all sizes, thanks to its affordability. From small tabletop devices to large industrial systems, perfect binding machinery caters to a wide range of needs. On-demand bookbinding has become increasingly popular, with many low-cost machines offering features once limited to high-production equipment. Perfect binding is ideal for a variety of publications, including catalogs, paperback books, and magazines.

Leading Perfect Binding Brands

Perfect binding is popular in print and finishing shops, from small to large. The machines range from affordable tabletop devices to high-end systems. On-demand binding has led to the development of numerous low-cost machines that offer features previously available only in high-production systems. Perfect binding is a versatile option for many types of publications, including catalogs, paperbacks, and magazines.

Perfect Binding Machine Comparison

The right perfect binding machine for you depends on your binding needs. For small schools, churches, offices, or print shops, a manual system like the Fastback 20 is ideal. However, for larger institutions or print-on-demand companies, an industrial machine is necessary.

Perfect Binding

If you're considering perfect binding, it's essential to weigh your options carefully. While it's a popular choice for catalogs, directories, and paperbacks with a higher page count, it's not suitable for every project. Explore different bookbinding styles to see if perfect binding is right for you.

For personalized advice, contact our print professionals. We’re here to help you get started with your books or brochures!